|

|||

The working principle of

WZ type circulating outside the vacuum evaporation device is mainly composed of tubular heater, evaporation tank, circular tube and other ancillary equipment.

Material liquid after the heater tube is heated to boiling point, part of the water evaporation, upward movement that heat energy is converted to kinetic energy; Gas-liquid mixture at the same time because of the heat tube and circular tube not produced a severe difference between boiling material liquid, under the induction of swelling kinetic energy and heavy difference, produced the material liquid natural circulation (in heating tube of material liquid circulation velocity is less than 1 m/s), the material liquid by the more heat, boiling the better, the greater the speed loop. Because it is under the effect of vacuum evaporation, the material liquid evaporation temperature can be controlled to some extent below 50 ℃. Evaporation of the secondary steam by silk screen defoaming and liquid precipitator capture after being taken away by hydraulic jet pump of water condensation. Evaporation tank material liquid after centrifugal spinning along the outer loop back to the bottom of the heater tube, recirculation heating evaporation, so cyclic heating evaporation (about 15 to 20 minutes), when meet the requirements of concentration, began to continuous discharge, at the same time also continuous feeding, so as to form a continuous vacuum concentration operation.

The main features

In order to improve the effect of gas-liquid separation, and have a function of defoaming, prevent entrainment, used the three-stage separation, capture mode: one is steam-liquid tangent into the evaporation tank use of centrifugal force and tank settlement; The second is the efficient air filter type filter layer evaporator on the top; Three is to establish the impact type liquid precipitator, thereby preventing the material liquid is secondary steam entrainment loss, even for bubble generating material liquid containing (such as soap liquid medicine) can achieve satisfactory separation effect. < BR > & have spent For ease of cleaning, set up a quick open the lid on the top of the heater. In the upper portion of the evaporation tank gas filter type filter sets the annular spray pipe cleaning. And set up on evaporative tank manhole for tank cleaning.

For convenience of observation in the operation, on the top of the heater and the evaporation tanks are equipped with light hole with lens.

WZ type evaporator with domestic commonly used membrane type, falling film type, litres - falling film evaporator, compared to WZ type circular evaporator, the material liquid enrichment ratio is large, and the tube is not easy to scale. For example used for potions solution concentration proportion of d = 1.25 and tube does not scale.

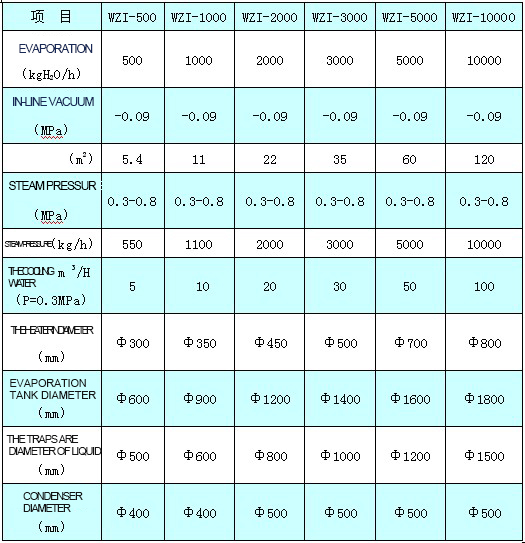

Technical parameters

Scope of application

WZType evaporator can be widely used in medicine, food, chemical industry, light industry, such as water or organic solvent evaporation concentration. Especially suitable for heat-sensitive materials (such as water, alcohol extract of production of traditional Chinese medicine, antibiotics fermentation liquor, milk, fruit juice, continuous enrichment under vacuum conditions in low temperature, to ensure product quality。